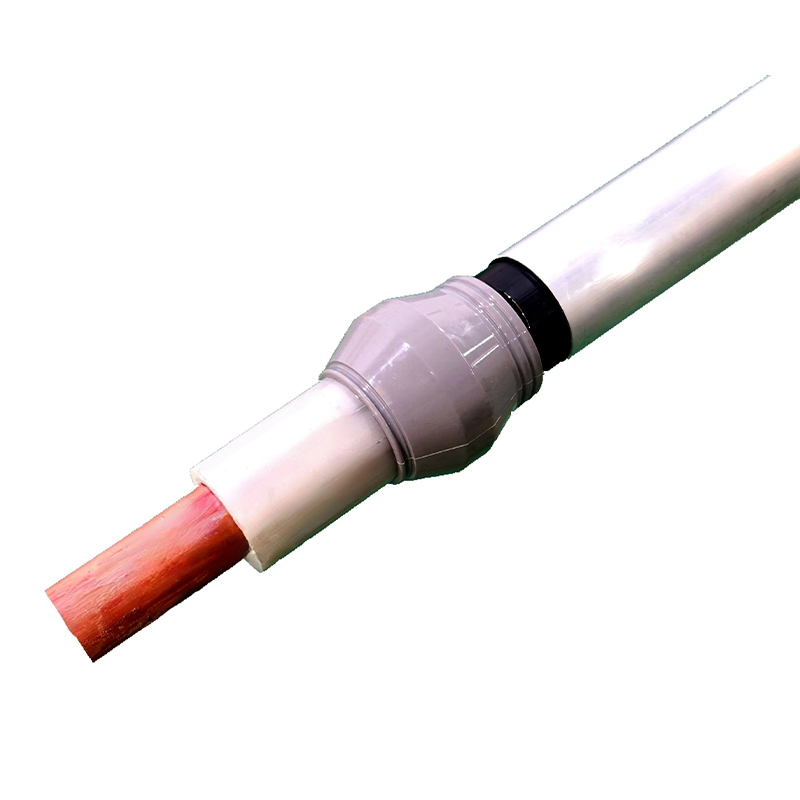

During the production process, it is necessary to strictly control the extrusion temperature and cooling rate of the insulation layer to avoid micropores or cracks inside the insulation layer due to process defects.

- +86-18621320918

- 13651889697@139.com

- No. 66, Chunzhong Road, Xinzhuang Industrial Zone, Shanghai